Coatings and screen printing

Painted and finished metalCarefully finished surface

Surface treatment services can be found in the premises of our second hall. We carry out the passivation of aluminum parts (Iridite NCP), powder coatings, screen printing and laser marking. Typical notable products include equipment plates, front panels and enclosures.

Iridite NCP

Iridite NCP stands for passivation of aluminum. This chemical coating process is RoHS compliant and prevents component corrosion as well as improves electrical conductivity. The passivation treatment also serves as a good adhesion surface for the parts to be painted. Iridite NCP treatment does not contain harmful compounds such as chromium.

Powder coating

Powder or powder coating is a surface treatment that is suitable for metal products. As a process, it is fast, inexpensive and environmentally friendly because it does not generate harmful VOC emissions. The finished paint surface is very resistant to abrasion and shocks.

Max. dimensions:

- width 30 cm

- height 80 cm

- length 120 cm

Screen printing

Screen printing is a printing method that requires long-lasting printing and precision. Particularly in large quantities, screen printing is generally the most advantageous and sensible printing method.

Max. work area:

- width 800 mm

- length 650 mm

- height 165 mm

We carry out other surface treatments together with our reliable partners.

Brilliant mechanics factory

See also our production methods

Steel and aluminum cutting

We cut sheet metal in a versatile and efficient manner in our own production.

Welding and laser welding

Our production includes versatile welding machines and technology for welding products made from sheet metal.

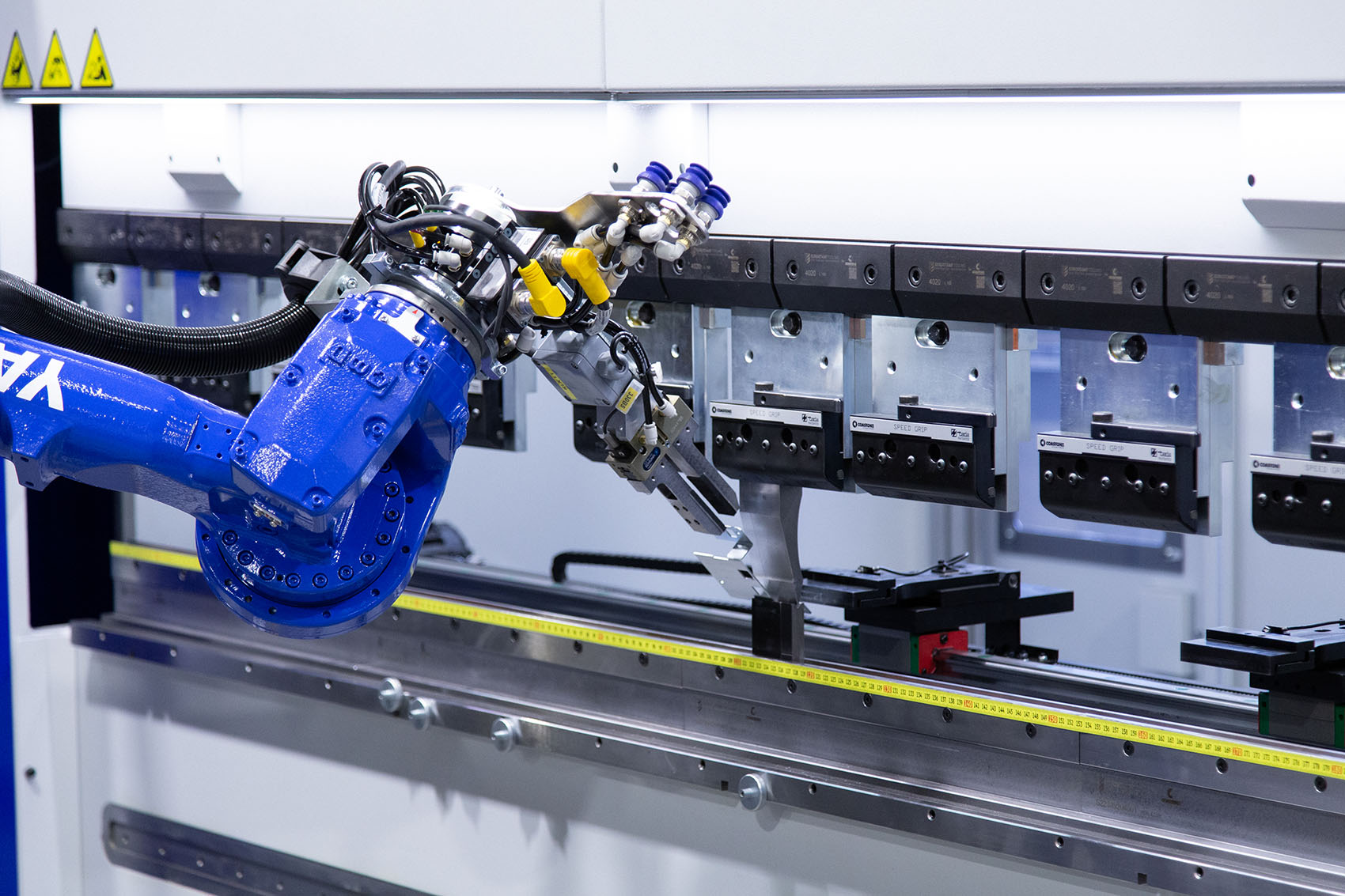

Press-brake bending and clinching

New! We perform press-brake bending and clinching in an automated robotic unit.

Machining

Machining plays an important role in the manufacture of mechanical assemblies.

Coating and painting

We also do coatings and powder coatings for sheet metal products under one roof.

Screen printing and laser marking

Fine texts and graphics on the surface of sheet metal products by printing or laser marking.

Assembly and testing

In addition to high-quality components, we offer our customers mechanical and electrical assembly and testing services.

Reliable partner

We are the challenger of tomorrow who wants to succeed together with our customers today!

Do you want a reliable partner who has the ability to listen, innovativity to develop, understanding to apply, agility to implement and will to serve the customer?

Request a free demo, and let's think together about the best manufacturing methods for your parts!